- Senyesemane

- Sefora

- Sejeremane

- Sepotoketsi

- Sepanish

- Russian

- Majapane

- Korean

- Searabia

- Irish

- Greek

- Turkish

- Setaliana

- Danish

- Seromania

- Indonesia

- Czech

- Setsi sa Afrikaans

- Sweden

- Se-Poland

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Sealbania

- Amharic

- Armenia

- Azerbaijani

- Belarusian

- Bengali

- Bosnia

- Bulgaria

- Cebuno

- Chichewa

- Corsicast

- Kroatia

- Dutch

- Estonia

- Filipino

- Sefinnishe

- Frisian

- Se-Galician

- Segeorgia

- Segujarati

- Haiti

- Hausa

- Hawaiian

- Sehebera

- Hmong

- Hungary

- Se-Icelandic

- Igbo

- Javanese

- Kananada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvia

- Lithuanian

- Lithuanian

- Macedonia

- Malagasy

- Semalay

- Malayalam

- Malta

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persia

- Punjabi

- Serbia

- Sesotho

- Sinhala

- Slovak

- Se-Slovenia

- Somali

- Samoa

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Seswahili

- Tajok

- Setamil

- Telugu

- Thai

- Seukraine

- Urdu

- Uzbek

- Vietnamese

E hlahisitsoe

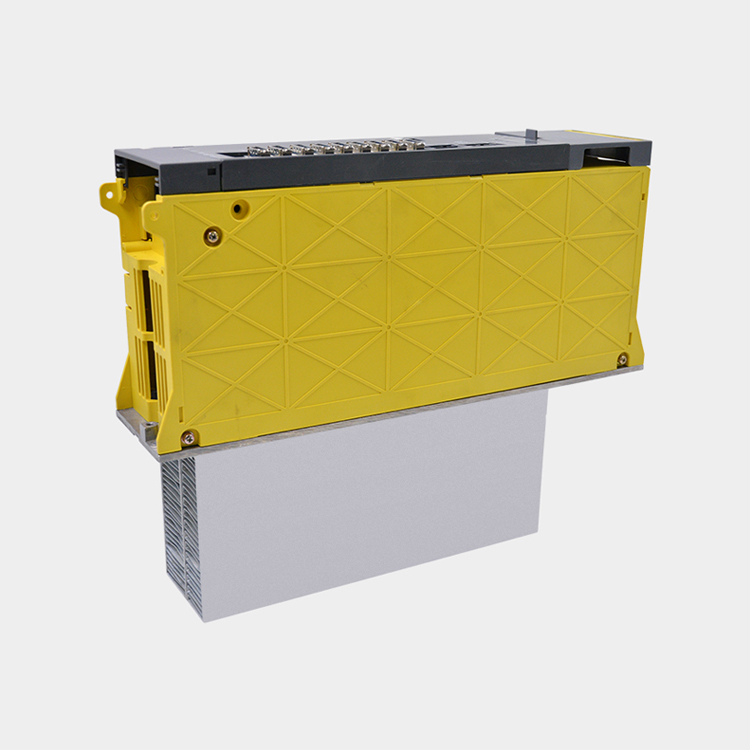

Wholesale Vector Ac Serviet Ac Driver: Fanuc A06b - 0115 - B203

Litekanyetso tsa sehlooho tsa sehlahisoa

| Paramente | TLHOKOMELISO |

|---|---|

| Nomoro ea mohlala | A06b - 0115 - B203 |

| Tšimoloho | Japane |

| Boemo | E ncha ebile e sebelisoa |

| Waranti | 1 selemo (New), likhoeli tse 3 (tse sebelisitsoeng) |

| Kopo | CNC Mechini ea CNCAN |

Litlhaloso tse tloaelehileng tsa lihlahisoa

| Tšobotsi | Lintlha |

|---|---|

| Lisebelisoa tsa maikutlo | Accoders, e lekang |

| Ts'ebetso | Precization e phahameng le katleho |

| Meetso ea Puisano | Ethercat, Modbus, Canopen |

Ts'ebetso ea lihlahisoa tsa sehlahisoa

Mokhoa oa ho etsa lintho tsa Vector AC Sething Mokhanni o kenyelletsa mekhahlelo e mengata ho netefatsa hore o na le bonnete le bonnete. E qala ka ho rala masela a laoletsoeng aloctor, a sebelisa li-dss tse tsoetseng pele ka tsona kapa tsa Microcontrord. Likarolo li khethiloe ka nepo bakeng sa ho boloka le ho nepahala, ho kenyelletsa le Pelita - Litlamorao tsa boleng le litšenyehelo. Ts'ebetso ea kopano e kenyelletsa lishekele tsa boleng ba boleng ho kopanya likarolo tsena, li bolela bohloka pakeng tsa lisebelisoa tsa Hardware le tsa sokolose. Post - Kopano, histone e 'ngoe le e' ngoe e tiile ka thata tlasa maemo a fapaneng ho netefatsa li-benchmark tsa ts'ebetso. Ts'ebetso ena e hatisa boitlamo ba rona ba ho fana ka bakhanni ba batšoaruoa ba tšepahalang, ba sa sebetseng hantle ba loketseng likopo tse fapaneng tsa indasteri.

Maemo a Kopo ea Sehlahisoa

Vector Ac Servotic Lithuthuthu li na le bohlokoa ba liindasteri tse fapaneng tse batlang e le hantle le ho arajoa haholo. Linakong tsa indasteri, li laola litsebi tsa ho iphetetsa le liroboto ka ho nepahala. CNC Mechini ea CNCOS e fetisa bakhanni bana bakeng sa boemo bo nepahetseng ba sesebelisoa bo hlokahalang maemong a pharallang. Indasteri ea Sehamimonductor e ba sebelisa ka tsela e sa sebetseng le tlhahlobo ea mahlo ka lebaka la bokhoni ba bona bo potlakileng. Likopo tsa Aerospace, ho kopanyelletsa le li-simletor tsa lipapali le lits'ebetso tsa tataiso, itšetleha ka ho ts'epahala le ho nepahala ha tsona. Ho feta moo, ka lefaphang la likoloi, ba ntlafatsa katleho le ho shebella liroboto tsa ho hlapaola le mela e ikemetseng.

Sehlahisoa kamora - Tšebeletso ea thekiso

Re fana ka limpho ka mor'a - Litšebeletso tsa thekiso, ho kenyeletsa le 'ngoe - Sesole sa Tlhaloso e Ncha le Tse tharo - Khoeli ea Khoeli ea Khoeli e sebelisitsoeng. Sehlopha sa rona se inehetseng se fana ka tšehetso ea tlhokomelo, ho netefatsa hore na mokhanni oa koloi ea motor oc Sething ac o sebetsa hantle. Re boetse re fana ka lits'ebeletso tsa ho lokisa le ts'ehetso ea tekheniki, re sepheo bakeng sa liqeto tse potlakileng le likarabo tsa litšebeletso tsa bareki nakong ea lihora tse 4 - lihora tse 4.

Tsamaiso ea Lihlahisoa

Sehlopha sa rona sa thepa ea thepa e etsa tlhahiso e bolokehileng le e potlakileng ea phepelo ea Wholele Vector Ac Sething Mokhanni ba Ac Sething lefatšeng ka bophara. Ka li-warehouse tse 'ne ka thata, re khona ho romella thepa e potlakileng ka tnt, Dhl, adEx, ems, e tiisa hore o tla o fihlela o sa sebetse hantle.

Melemo ea sehlahisoa

- Tlhaloso e kholo: e tiisa hore taolo e ntle le ea lebelo.

- Katleho ea motlakase: e fokotsa litšenyehelo tsa ts'ebetso.

- Lipehelo tse fapaneng: E loketse indasteri e fapaneng.

- Ho tšepahala: E hahiloe ka likarolo tsa polokeho bakeng sa nako e telele - tšebeliso ea nako.

FAQ ea sehlahisoa

- Monyetla oa mantlha oa ho sebelisa veke ea veke ea AC Sertono AC?Molemong oa mantlha ke taolo e nepahetseng holim'a motho ea makoloi, velocity, le torque, e e etsa hore e phahame -

- Warrant e fanoa bakeng sa likarolo tse ncha?Re fana ka 1 - Sesole sa Selemo se Seng Servictor Ac Servo motsoele.

- U ka tsamaisa litaelo kapele hakae?Ka lintlha tse ngata le li-warehouse tse ngata, re romella tse ngata tse sebelisang kapele ho sebelisa batsamaisi ba tšepahalang.

- Li sebelisoa metsoako e tšepahalang?Ee, likarolo tsohle tse sebelisetsoang li lekoa ka botlalo 'me li na le 3 - Khoeli ea Khoeli.

- Na mokhanni a ka kopana le litsamaiso tse ling?E, e ts'ehetsa puisano ea puisano joalo ka ethercat, Modbus, le kichineng bakeng sa ho ikopanya le tšoaetso.

- O fana ka tšehetso ea ho kenya?Sehlopha sa rona sa tšehetso sa mahlale se fumaneha bakeng sa tataiso ea ho kenya le ho rarolla mathata.

- Ke indasteri efe ea hore li indasteri e ruisa molemo ka sehlahisoa see?Liindasteri tse kang tsatohonom, cnc hochingning ea cnc ea ho fana ka letsoho, ho etsa Aerospace, le molemo oa kokotatho.

- Vector o laola ts'ebetso joang?Taolo ea vector e lumella tao e ikemetseng ea literaka tsa makoloi, ho ntlafatsa ho nepahala le botsitso.

- Na u fana ka litšebeletso tsa ho lokisa?E, re fana ka litšebeletso tsa ho lokisa e le karolo ea rona kamora - Tšehetso ea thekiso.

- Ke lintlha life tsa polokeho tse kenyelelitsoeng?Bakhanni ba rona ba kenyelletsa ts'ireletso e fetang e phethahetseng le e tšehali, hammoho le bokhoni ba tšohanyetso ba tšohanyetso.

Lihlooho tse chesang tsa sehlahisoa

- Ho kopantsoe le lits'ebetso tsa sejoale-joale tsa thuto ea pele: Li-victor tsa rona tse rekisoang a AC Sething li kopanya mekhoa ea sejoale-joale ka mekhoa ea ho ikatisa ea sejoale-joale, e tšehetsang itokelo e tloaelehileng - Protocol e tloaelehileng e kang Ethercat le Modbus. Sena se etsa hore puisano e bonolo le taolo e tsamaisang maikutlo, e etsa hore ho be bonolo ho hloka maemo kamehla ka mehla - libaka tsa liindasteri.

- Tsoelo-pele ea Mahlale a Taolo ea Morekisi: Khatiso ea veked ea veked ac Sething motsoele e tsamaisoa haholo ke nts'etsopele ea theknoloji ho laola li-algorithms le ts'ebetso ea dijithale. Lihlahisoa tsa rona li kenyelletsa liketsahalo tsena tsa morao-rao, tse bakiloeng ke ntlafatso ea mokolo, le ho nepahala ha laola, ho re beha ntle le tlhophiso - indastering -

- Ts'ebetso ea Matla ea Matlapeng ea Lipuoeng tsa indasteri: Tšebeliso ea matla ke ntho e bohlokoa ka ho fetisisa lits'ebetsong tsa indasteri. Mekha ea rona ea veked Ac Sething e etselitsoe ho ntlafatsa ts'ebeliso ea matla ka maano a sebetsang, ka ho etsa joalo a kenya Litsebetso tsa Ts'ebetso ka Ts'ebetso ea Liindasteri.

- Ho netefatsa ho ts'epahala ka likopo tse mahlonoko: Ho likarolo tse kang Aerospace le ts'ireletso, ho ts'epahala ke hore ha ho monate. Bakhanni ba rona ba veked Ac Sething ba hahiloe ho mamella mathata a likopo tse tebileng, ho fana ka ho ts'epahala le ho nepahala ho netefatsa hore katleho e Phethahetseng.

- Tloaelo bakeng sa litlhoko tse fapaneng tsa khoebo: Ho ikamahanya ha bakhanni ba rona ba litoropong tsa rona ba lumellang ho latela litlhoko tse ikhethileng tsa indasteri. Hore na ke lisebelisoa tsa CNC, liroboto kapa thepa ea semiconductor, re fana ka tharollo e bontšang litlhoko tse fapaneng tsa tšebetso, ho matlafatsa boitlamo ba rona ba khotsofalo ea bareki.

- Sepotlolo sa theknoloji ho li-drive tsa Servo: Ho lula ha theknoloji ea mahlale, re tsoela pele re kenyelletsa boiphihlelo ba morao-rao ho khanna li-drive tsa rona tsa boitethi. Boitlamo bona ho etsa hore lihlahisoa tsa rona li lula tlholisano, li fana ka ts'ebetso e phahameng le bokhoni bo kopaneng bo kopanelang litlhoko tsa litlhokahalo tsa indasteri.

- Bohlokoa ba lisebelisoa tsa maikutlo: Lisebelisoa tsa maikutlo li bapala karolo ea bohlokoa ts'ebetsong ea veked ac Sething motsoele. Ka ho fana ka lintlha tsa nnete -

- Likarolo tsa polokeho le Ts'ireletso ea sistimi: Ho kenyelletsa le polokeho ea polokeho ea polokeho ea rona ea veked Ac Sething Ac Sething Ac Servo mouti e totobatsa boinehelo ba rona ho boloka polokeho ea ts'ebetso. Likarolo tse kang Ts'ireletso e Ntle le ea tšohanyetso li thusa mesebetsi ho thibela tšenyo ea sistimi, e hlalosang ts'ebetso e sireletsehileng ea sitisang.

- Mekhoa ea nako e tlang ho Theknoloji ea Botho ea Servo Motor: Bokamoso ba The Servo motor theknoloji ea mahlale a Thepa ea Serdo Motor Technology e tswa ho ea bohlanya, ho kopantšela Tharollo. Lihlahisoa tsa rona li entsoe ka bokamoso bona, bo fana ka bokhoni bo matla ba taolo ea ho laola le likhetho tse lokiselitseng liindation bakeng sa taolo le taolo e tlang.

- Karolo ea DSP ho Bakhanni ba Servo motsoal: Lits'ebetso tsa dijithale (DSP) li hlophisehile ho etsa bakhanni ba seithuti sa sejoale-joale, ho thusa lipalo tse rarahaneng le tsa sebele - taolo ea nako. Ts'ebeliso ea rona ea theknoloji e hlophisitsoeng e tsoetseng pele ea DSP e tiisa hore bakhanni ba rona ba fana ka ts'ebetso e phahameng le ho nepahala ts'ebetsong e fapaneng.

Tlhaloso ea setšoantšo

Mekhahlelo ea sehlahisoa

Shebana pele le ho fana kaé Tha Thal Tha Solang ka lilemo tse 5.